Precision. It’s at the heart of everything we do.

Welcome to Precision Technologies Group

Innovation

at its Finest

Ever since our business was formed in 1860, our name has been synonymous with precision. Today, our group comprises PTG Holroyd Machine Tools, PTG Friction Stir Welding Machines and PTG Holroyd Precision Rotor Milling Machines.

PTG

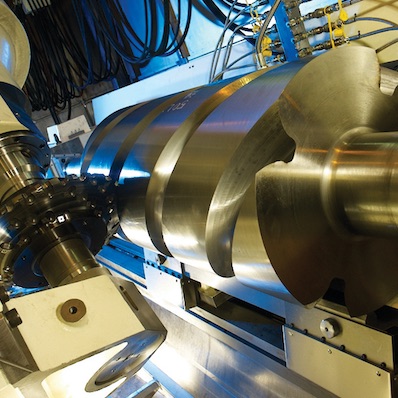

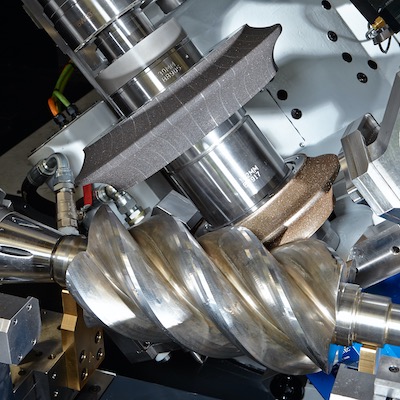

Holroyd Machine Tools

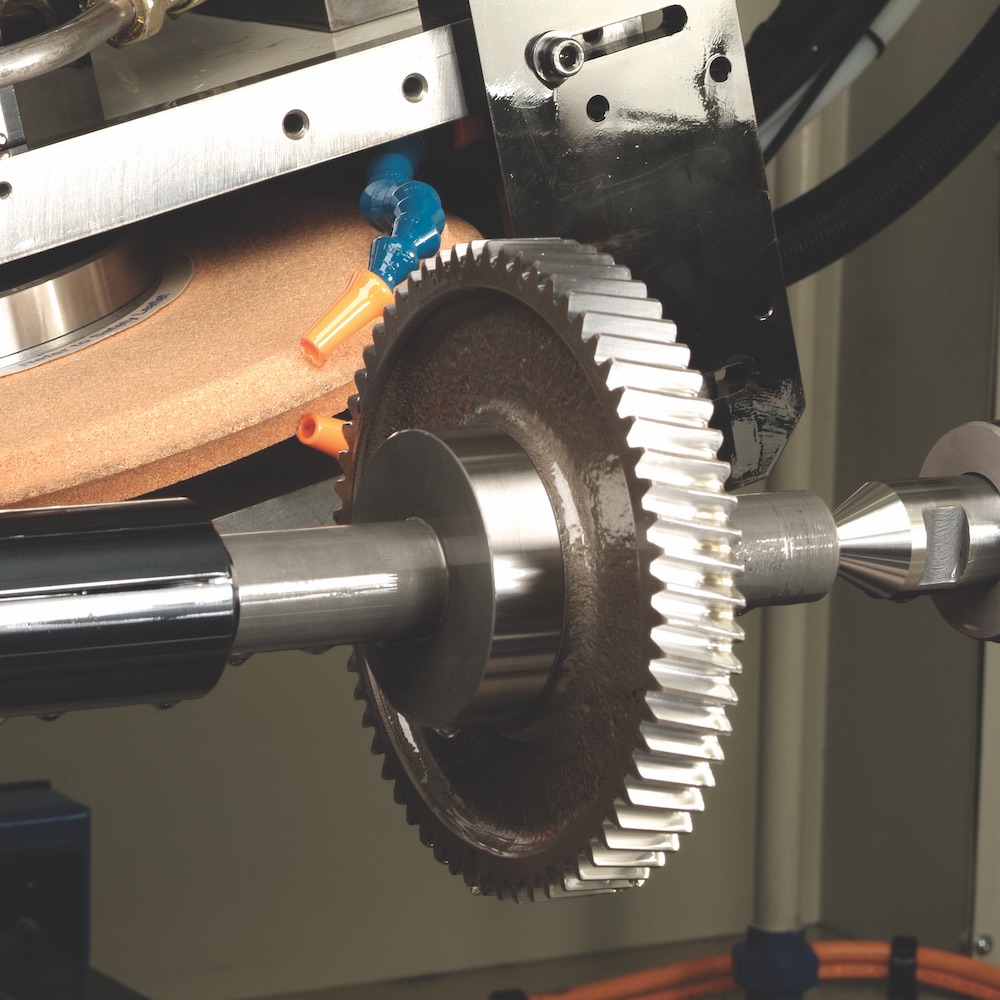

PTG Holroyd’s gear, rotor, thread and pump-screw milling and grinding machines produce the world’s most accurate helical components.

PTG

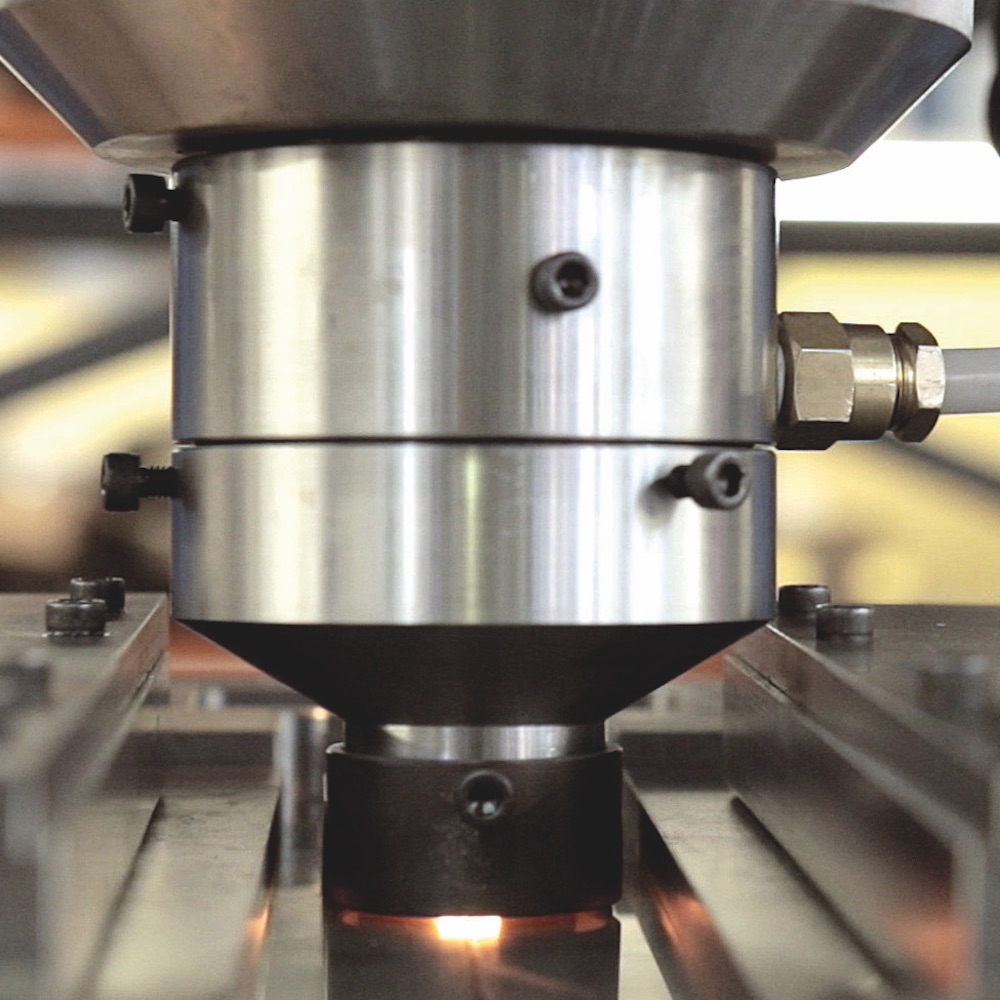

Powerstir Friction Stir Welding

PTG Friction Stir Welding’s Powerstir FSW machines enable manufacturers in sectors as diverse as automotive, aerospace and high-speed rail to create lightweight, superior, high-strength joints.

PTG

Holroyd Precision Rotors

From production facilities in the UK, USA and China, PTG Holroyd Precision Rotors uses PTG Holroyd machines to manufacture ultra-precise helical components, in batch sizes from prototype to high volume.