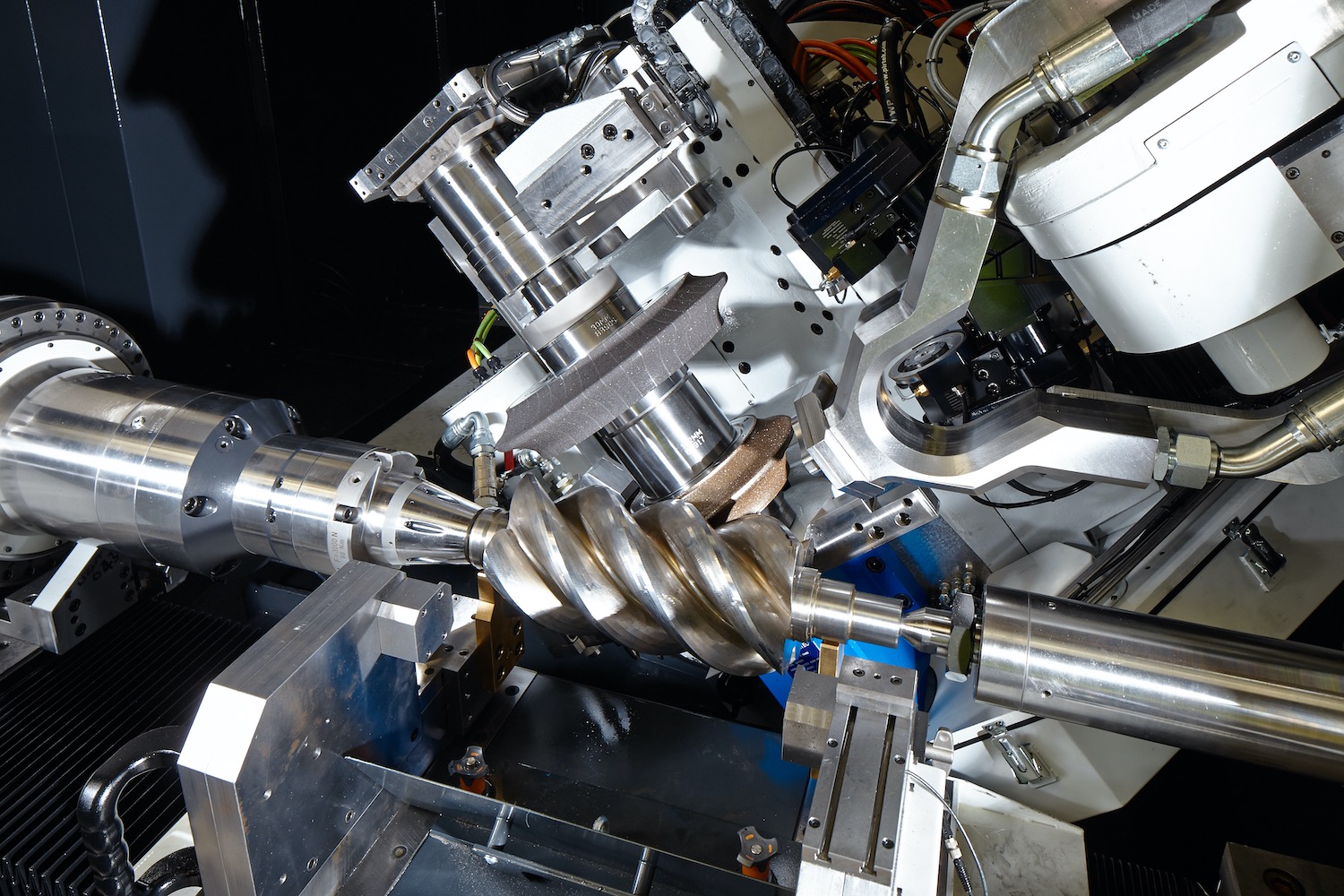

In addition to being a high-precision helical profile grinding machine, the Zenith 400 also delivers high stock removal rates and aggressive semi finishing, with production rates and accuracies tailored to individual manufacturing requirements.

Holroyd Profile Management System (HPMS)

Available as an option with several of our grinding technologies, HPMS consists of a suite of sub programs for the development of a wide range of helical profiles for screw rotors, vacuum screws and pump screws. HPMS can also be used to assist the control of a profile during the production stages and optimisation of operating meshing conditions.