News & Press

Leading Chinese helical component manufacturer chooses Zenith of helical profile grinding

UK-based PTG Holroyd Precision is to supply one of its ultra-precise Zenith 400 helical profile grinding machines to a leading Chinese manufacturer of helical components.

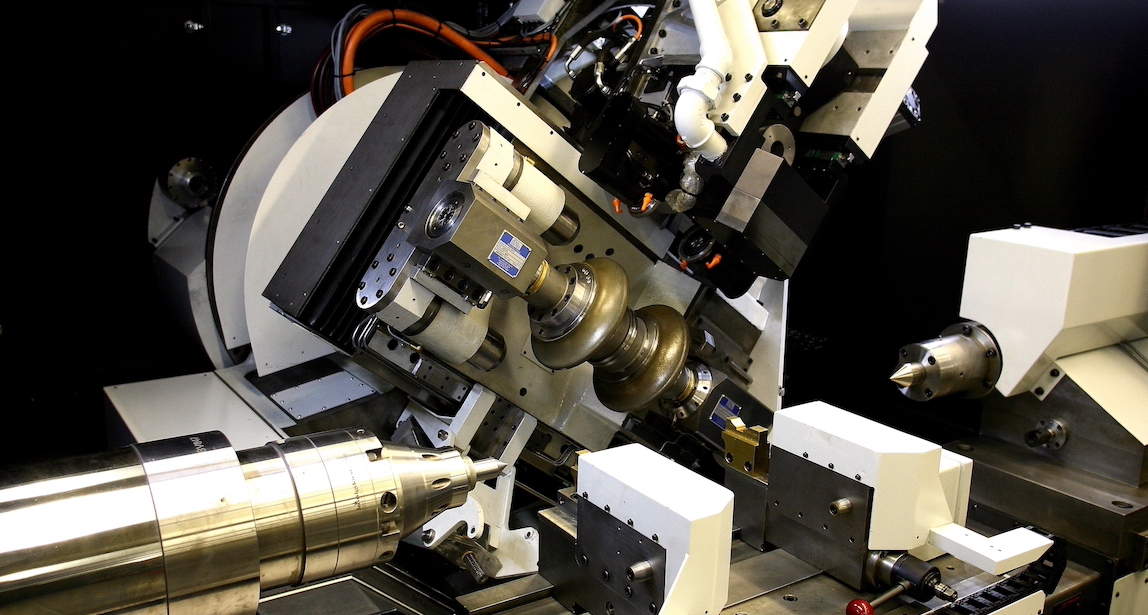

Developed to precision grind components weighing up to 700 kg and measuring up to 420 mm in diameter, 2.2 metres in length, and with a maximum 100 mm profile depth, the Zenith 400 combines high stock removal rates with aggressive semi-finishing. It offers production rates and accuracies tailored to the most demanding of manufacturing strategies.

Scheduled for installation at the Chinese company’s Chongqing-based production facility in summer 2025, the Zenith 400 is equipped with PTG Holroyd’s proprietary dual grinding wheel system. This capability will enable operators to use either a 500 mm vitrified, dressable aluminium oxide grinding wheel for exceptional versatility in production strategies and product development, or diamond-hard plated CBN roughing and finishing wheels for cost-effective volume production.

“With the advantage of two grinding wheels, our customer will be able to complete both rough-grinding and finish-grinding in one seamless operation,” comments PTG Holroyd Precision’s Sales Director, Mark Curran. “By using CBN grinding wheels for both grinding processes, they will benefit from significantly reduced cycle times and improved heat dissipation. Thanks to the greater resistance of CBN, they will also enjoy extended wheel life, with no need for dressing, even at high stock removal rates.

“We are extremely pleased to have received this significant machine tool order,” adds Mark Curran. “In addition to the Zenith 400’s well-proven capabilities, its dual grinding wheel capability was clearly a major attraction to the customer in view of the efficiencies this will bring to their production processes.”

The Zenith 400: at the pinnacle of helical profile grinding

Providing considerable flexibility in helical profile grinding, the Zenith 400 features advanced development and production software, making it well-suited to all user requirements, whether that is research & development or mass production.

Key features of the Zenith 400 helical profile grinding machine include:

- Vitrified Al2O3 and plated CBN grinding wheel options

- Accelerated setup, with fully automated grinding wheel balancing system

- Powerful, menu-driven touchscreen programming

- High stock removal rates, aggressive semi-finishing and precision fine finishing

- Holroyd’s unique on-board 3D CMM component scanning probe with fully automatic compensation feedback

- High speed spindles and advanced in-process dressing systems to maintain profile accuracy and keep the grinding wheel in optimum condition

- Complete integration with automated parts handling systems