The Latest

News & Press

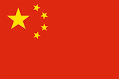

Discover the future of precision screw pump grinding

A brand-new PTG Holroyd CNC machine for the precision grinding of screw pumps is in the final stages of development at our Rochdale-based machine tool technology centre.

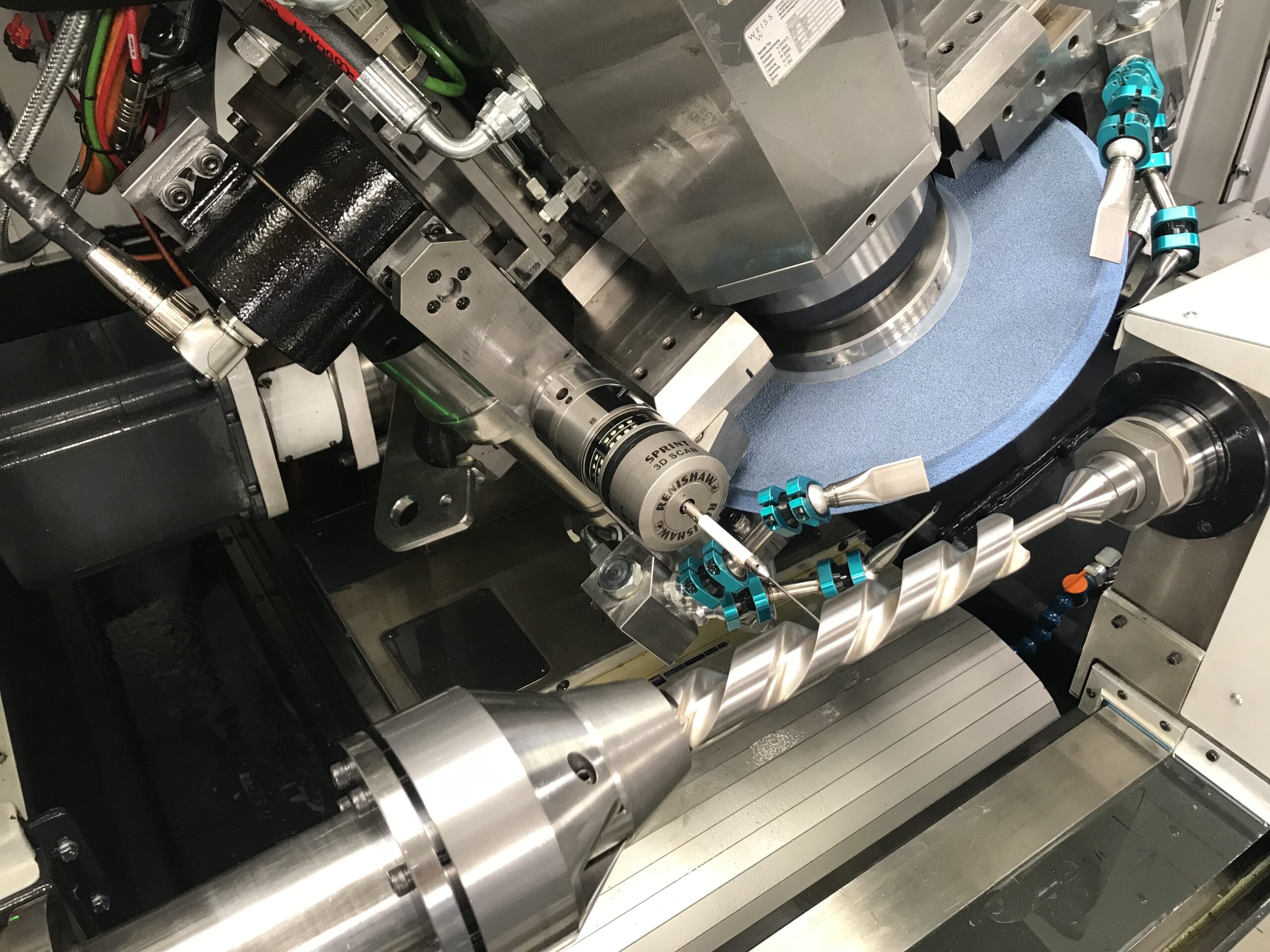

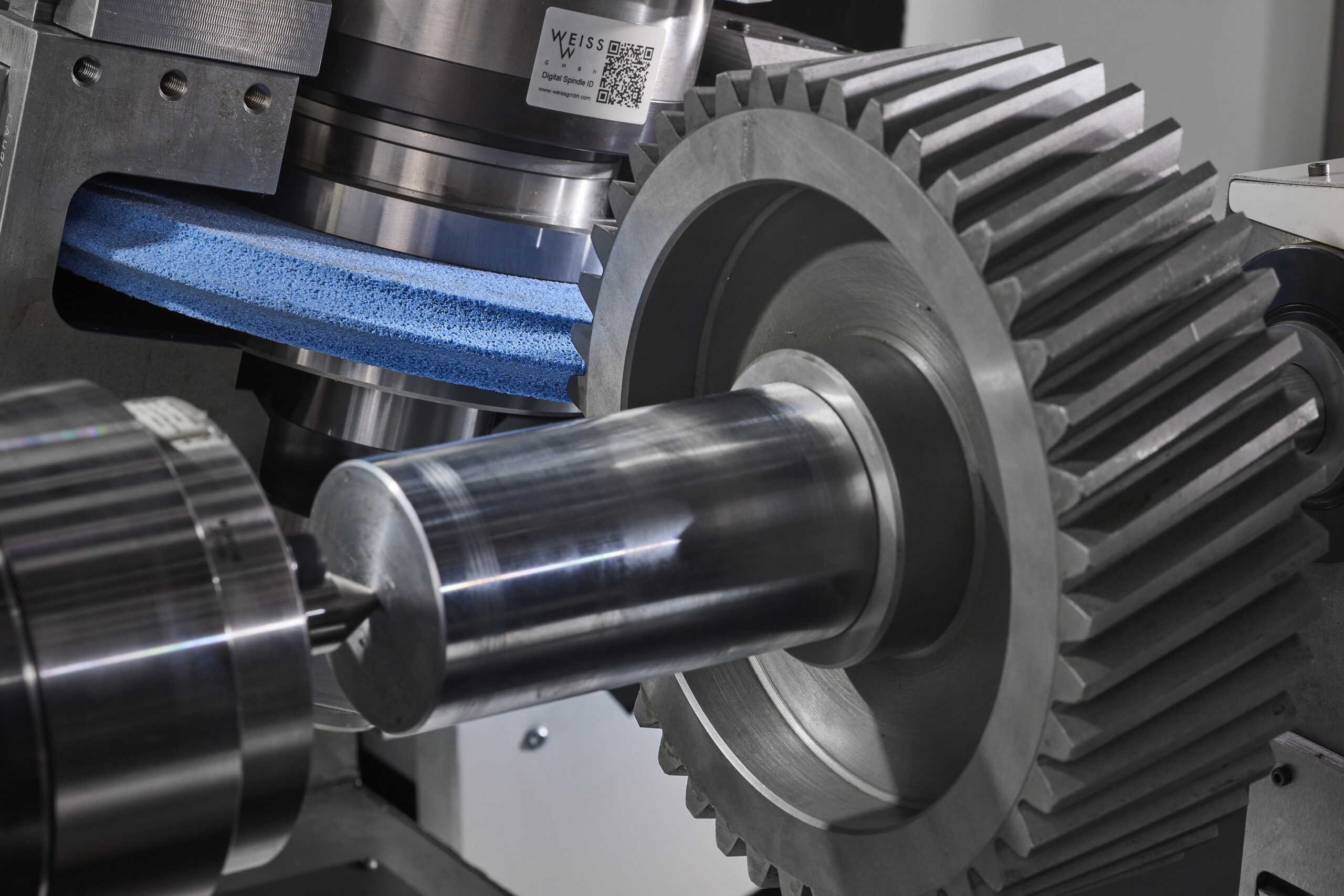

New PTG Holroyd machine is first of kind to precision grind both worms and gears

Manufacturing high-accuracy worm gears and screws alongside precision spur and helical gears has traditionally required the use of two quite different CNC grinding machines. Thanks to PTG Holroyd’s newly launched HG350-WG worm and gear grinding centre, however, just one machine can now complete both tasks.

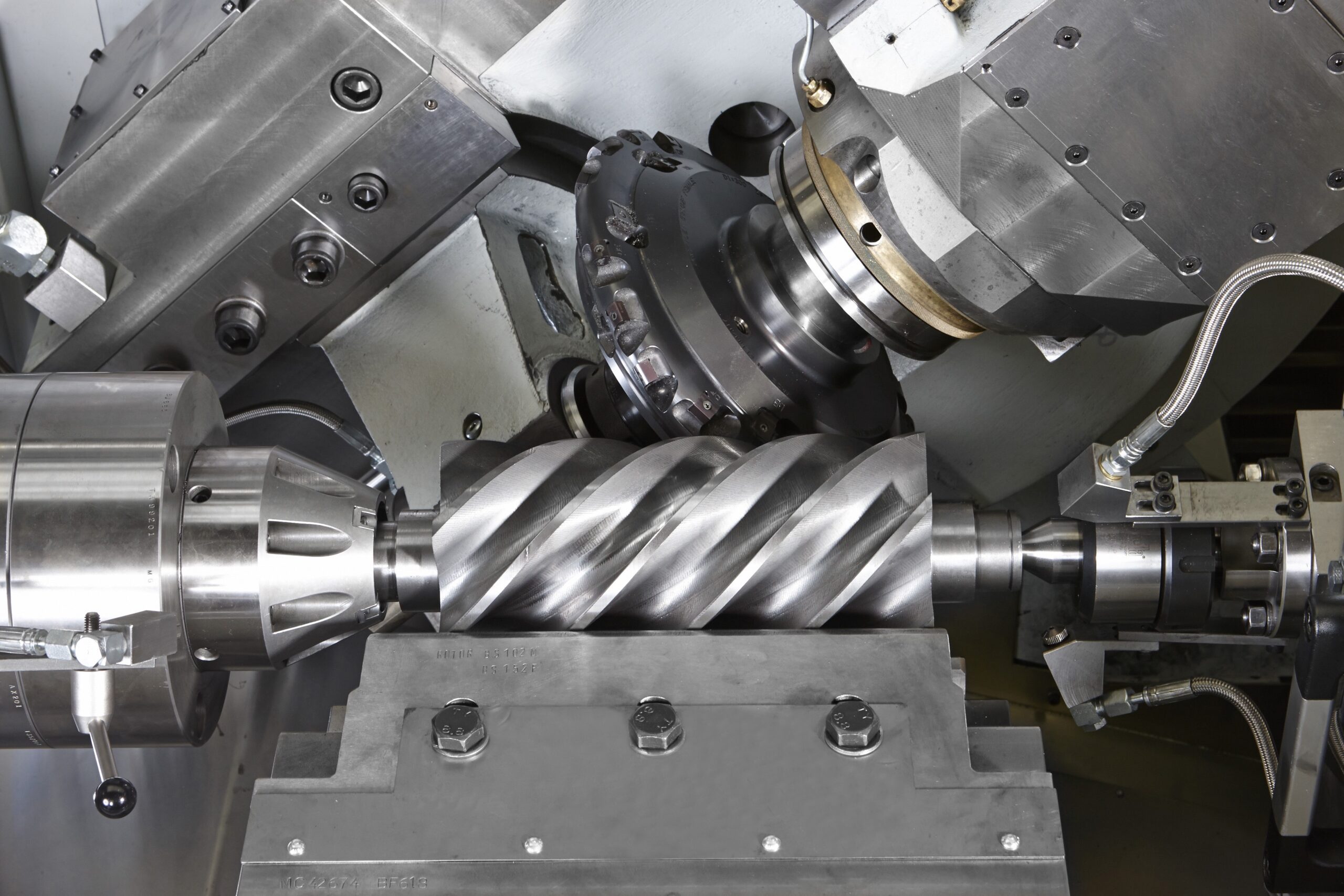

PTG Holroyd’s advanced ‘dual rotor milling technology’ is set to redefine Roots-type blower production for leading German manufacturer

A recently developed dual-purpose CNC rotor milling machine from PTG Holroyd is all set to revolutionise the manufacturing capabilities of a leading German maker of compressed air, gas and vacuum technologies. Currently in build at PTG Holroyd’s Rochdale-based machine tool technology centre, the machine, a PTG-Holroyd 4EX-R-BL (BL = blower) model, will be used to precision-mill both helical rotors and Roots-type blower air ends.

Holroyd tool management centre brings greater flexibility to global compressor manufacturer

One of the world’s leading manufacturers of refrigeration and air compressors has ordered a new PTG Holroyd CS700 tool management centre. The machine tool, which is currently in build at PTG Holroyd’s UK-based technology centre, will be shipped to one of the compressor manufacturer’s facilities in China’s Jiangsu province early next year.

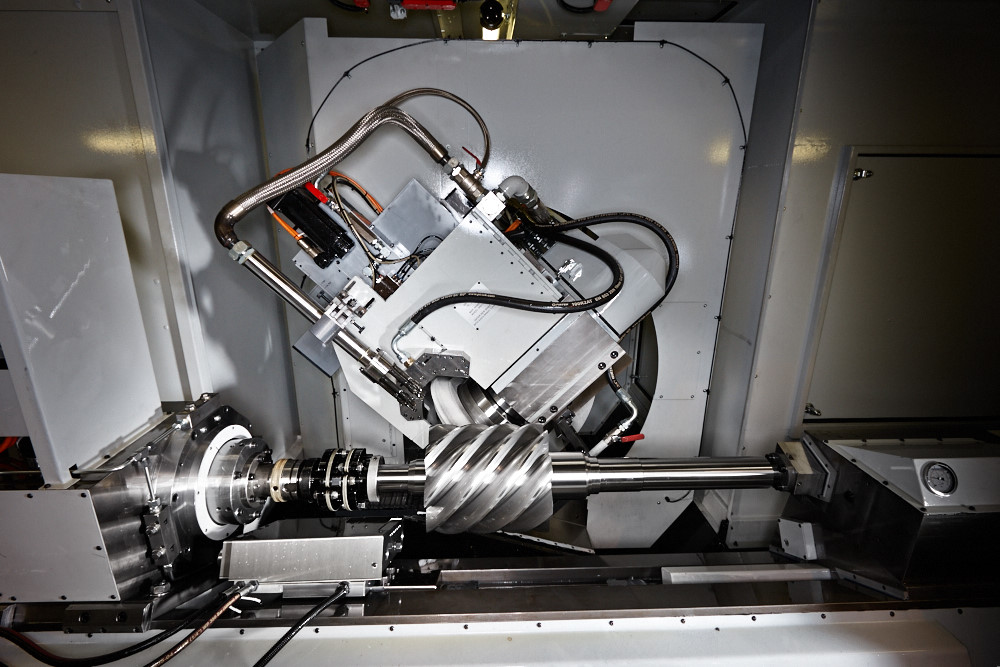

North American compressor manufacturer chooses second British-built PTG Holroyd rotor grinding machine

One of North America’s premier rotary screw compressor manufacturers has ordered a new, ultra-precise TG 350E CNC rotor grinding machine from UK-based PTG Holroyd.

Creating a stir: PTG to present Powerstir dual weld-head friction stir welding at Aluminium 2022

Stand 5L07 27 – 29 September 2022 Exhibition Centre, Düsseldorf UK-based Precision Technologies Group (PTG) will be showcasing its range of Powerstir dual weld-head friction stir welding (FSW) machines at Aluminium 2022.

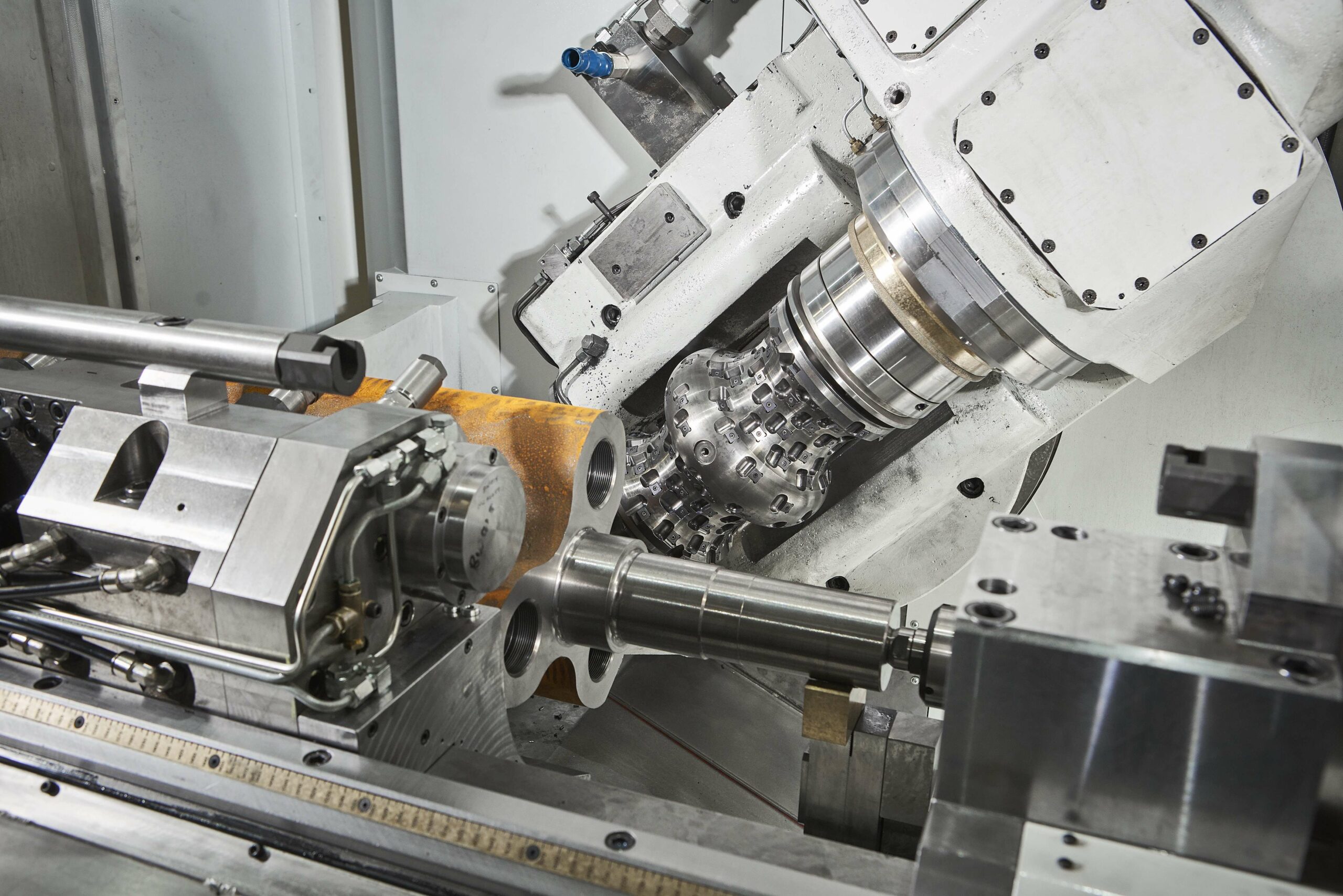

First of PTG Holroyd’s advanced new gear grinding centres ready to ship

The first of PTG Holroyd’s newly developed HG350 advanced gear and worm gear grinding centres are currently undergoing factory acceptance testing at the company’s Rochdale-based technology centre, in preparation for shipping to customers.

Seventeenth PTG Holroyd EX Series rotor milling machine for premier air compressor manufacturer

One of the world’s leading air compressor machinery specialists has ordered what will be its seventeenth EX Series rotor milling machine from UK-based PTG Holroyd. Scheduled for build at PTG-Holroyd’s Rochdale-based technology centre later this year, the machine, a 3EX-R model, will be installed at one of the air compressor company’s North American manufacturing facilities. Able to rough mill rotor blanks of up to 350 mm in diameter, it will be used to produce rotors for portable and stationary air compressors.

Chinese refrigeration compressor manufacturer chooses British-built PTG Holroyd rotor grinding machine

A leading Chinese manufacturer of industrial refrigeration compressors has chosen a British-built PTG Holroyd TG Series CNC rotor grinding machine to bring even higher levels of accuracy and speed to its manufacturing strategies.

Improving Screw Compressor Rotors: A Collaboration between Design and Manufacturing

The 12th biennial International Conference on Compressors and Their Systems, which took place at City, University of London in September 2021, included a fascinating joint industry presentation by Professor Christopher Holmes of PTG Holroyd and Jack Sauls (retired), formerly of Trane.